Watch Full Demo OVERVIEW Below

PRODUCTS

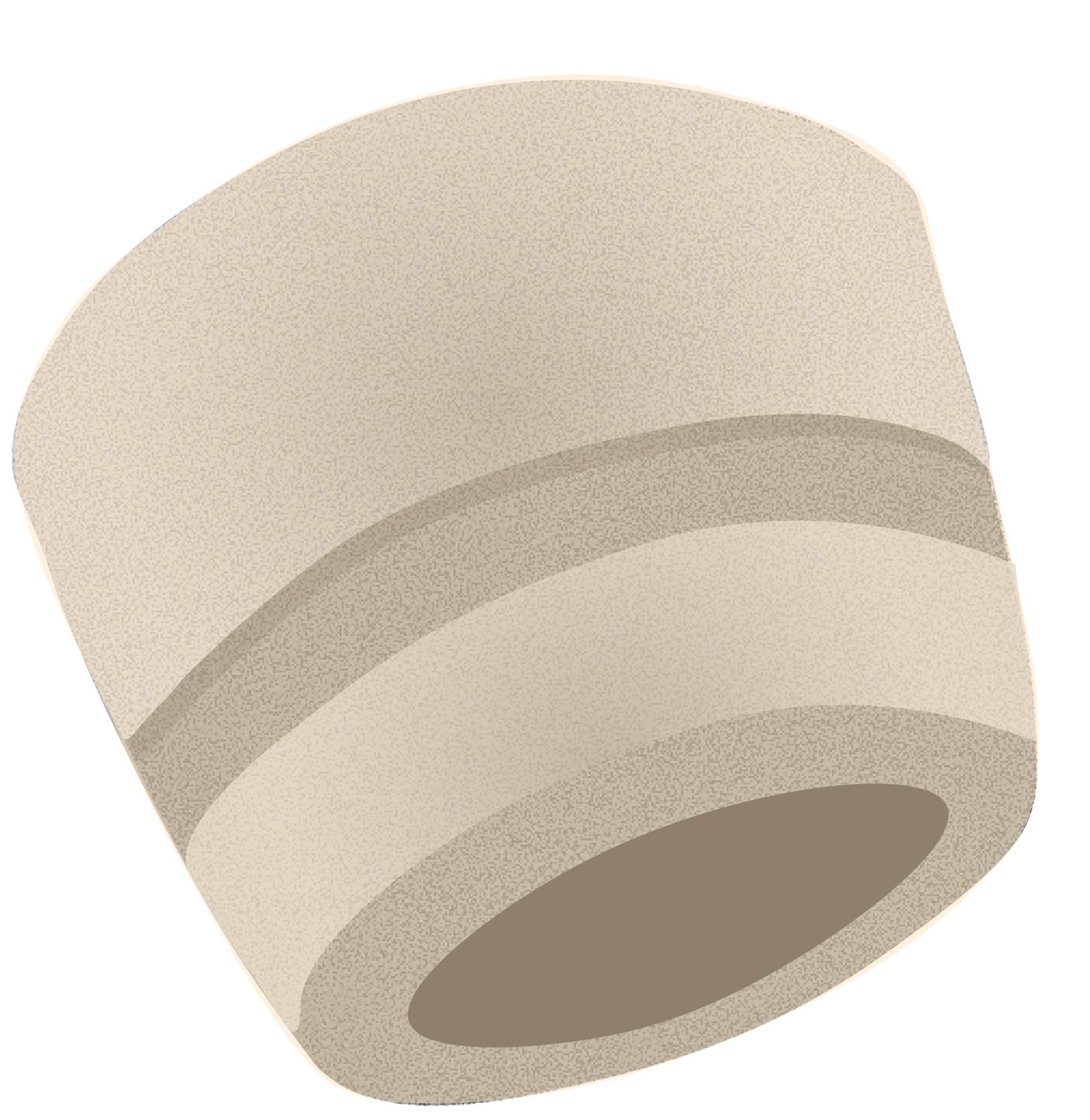

The complete Post Tension Plug system. Working over the slabs edge becomes easy when using the cordless right-angle drill by Milwaukee. This set-up allows the user to ream at a 45 degree angle even after the formwork has been removed. After the pocket has been cleared of debris by the cordless blower/brush, the user can use the grease cap checker to ensure that the cap has been properly seated. The final step of the process is to apply the 2-part epoxy to the entire circumference of the plug and push until flush with the slab. Each bucket of Post Tension Plugs comes 4 paintbrushes and 75 plugs.

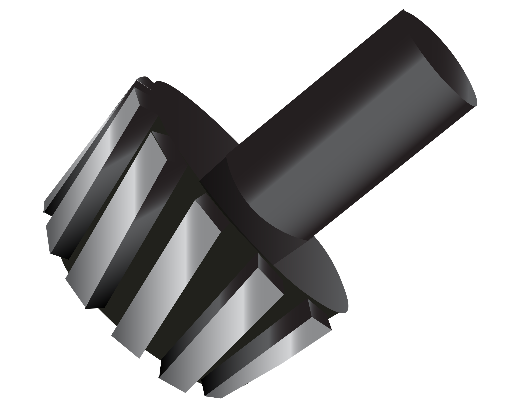

Reaming Tool

The Reaming tool's diamond plated teeth are designed to roughen the inside pocket, remove any grease coating, and create a uniform circumference that emulates the shape of the Post Tension Plug. When used properly, the combination of the reaming tool, Post Tension Plug, and a highstrength, two-part, non-sag epoxy creates a watertight seal that exceeds the capacities of traditional grouting in all measures.

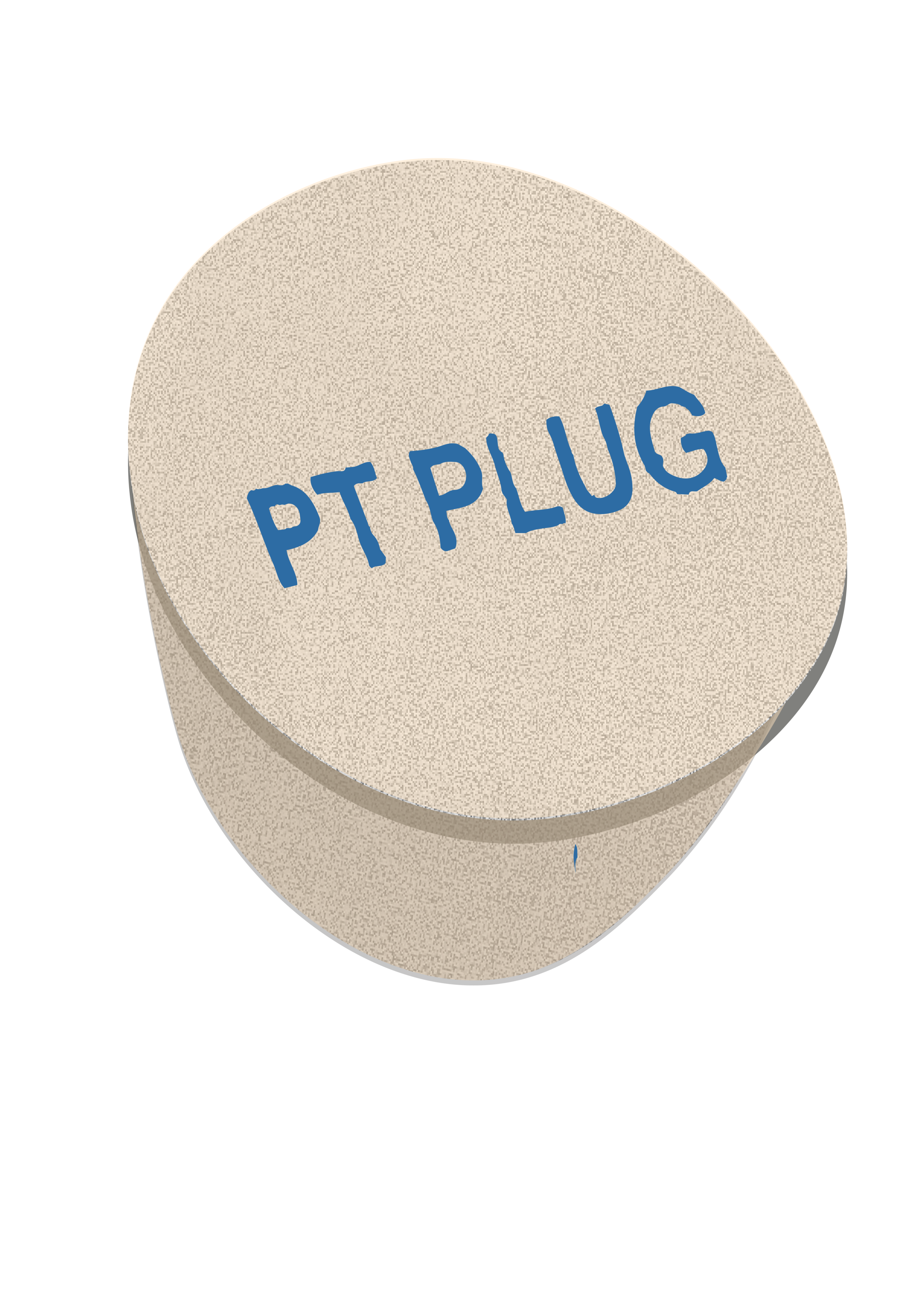

Post Tension Plug

The Post Tension Plug is designed to create a 100% watertight line of defense at the tendon’s stressing end. The PT Plug is made of high-strength, non-shrink, non-metallic grout (8000 PSI compressive strength at 28 days that complies with ASTM C-1107) and is precasted to fit into the tendon’s stressing pocket after the pocket is abraded using the Post Tension Plug Reaming Tool. The Post Tension Plug's 1" of coverage ensures that the tendon iscut correctly and the grease cap is properly seated. The Post Tension Plug's 1" of coverage ensures that the tendon is cut correctly and the grease cap is properly seated.